BEW (FH) Types

[Specifications]

| Model | BEW-1FH | BEW-2FH | BEW-4FH | |||||

|---|---|---|---|---|---|---|---|---|

| Input voltage | 100 V AC | ± 10% 50/60 Hz | ● | ● | ||||

| 200 V AC | ● | ● | ||||||

| 400 V AC | ● | ● | ||||||

| Input voltage range | AC80 ~ 130V | AC170 ~ 300V | AC80 ~ 480V | |||||

| Control method | Overexcitation (full-wave rectified) for 0.5 sec followed by constant excitation (half-wave rectified) | |||||||

| Overexcitation | Constant excitation | Overexcitation | Constant excitation | Overexcitation | Constant excitation | |||

| Output voltage | DC90V | DC45V | DC180V | DC90V | DC360V | DC180V | ||

| Output current | When the ambient temperature is 20℃ values in () are for an ambient temperature of 60℃ | DC1.6A (DC1.3A) Constant excitation | 1.2 A DC (1.0 A DC) Constant excitation | |||||

| Output capacity | When the ambient temperature is 20℃ values in () are for an ambient temperature of 60℃ | 72 W (58 W) Constant excitation | 144 W (117 W) Constant excitation | 216 W (180 W) Constant excitation | ||||

| Size settings | Purpose for use | Using overexcitation | Using weak excitation | Using overexcitation | Using weak excitation | Using overexcitation | Using weak excitation | |

| Clutch/brake rated voltage | DC45V | DC90V | DC90V | DC180V | DC180V | DC360V | ||

| ●: Applicable | 01 | ● | ● | ● | ● | ● | ||

| 02 | ● | ● | ● | ● | ● | |||

| 03 | ● | ● | ● | ● | ● | |||

| 04 | ● | ● | ● | ● | ● | |||

| 05 | ● | ● | ● | ● | ● | |||

| 06 | ● | ● | ● | ● | ● | |||

| 08 | ● | ● | ● | ● | ● | |||

| 10 | ● | ● | ● | ● | ● | |||

| 12 | ● | ● | ● | ● | ||||

| 14 | ● | ● | ● | ● | ||||

| 16 | ● | ● | ● | ● | ||||

| 18 | ● | ● | ● | ● | ||||

| 20 | ● | ● | ● | ● | ||||

| 25 | ● | ● | ● | ● | ||||

| Applied cutches/brakes | MIKI PULLEY electromagnetic-actuated clutches and brakes Rated voltage DC 45/90/180 V | Spring-actuated brake | ||||||

| Insulating resistance | Between terminal and body | DC 500 V, 100 M Ω with Megger | ||||||

| 2000 V AC, 50 Hz, 1 min. | ||||||||

| Usage environment | With no condensation | -20℃ ~ +60℃ | ||||||

| Mass | Per product | 0.065 kg | ||||||

[Dimensions]

[Structure]

[Terminals and Functions]

| Terminal symbol | Terminal name | Function description |

|---|---|---|

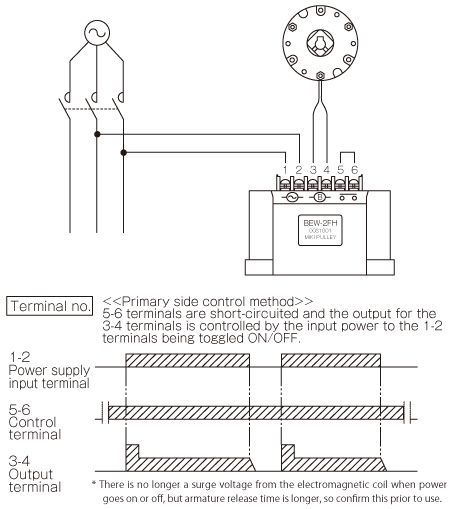

| 1-2 | Power supply input terminal | Connector for a commercial power supply |

| 3-4 | Output terminal | Connector for an electromagnetic clutch or brake |

| 5-6 | Control terminal | Output is controlled by opening and closing between terminals with a relay or other contact |

[Characteristics]

Used as Overexcitation Supplies

BEW(FH) models go through about 0.5 sec of full-wave rectified output and then transition to half-wave rectified output. BEW-FH power supply devices create an overexcitation state by matching their constant excitation voltage to the rated voltage of the electromagnetic clutch/brake to obtain the following effects.

• Longer electromagnetic clutch/brake service life (about double)

• Shorter armature pull-in time (about half) to achieve high frequency operation

• Longer service life (about double)

• Reduced startup interference by combined use of a spring-actuated brake and a motor

Also, the following effects can also be obtained by determining the specifications of the spring-actuated brake under the

assumption that a BEW-FH power supply will be used.

• Higher torque

• Thinner design and lighter weight

Use as a weak excitation power supply

Conversely to the above, matching the overexcitation voltage of the power supply unit to the rated voltage of the electromagnetic clutch and brake produces a weak excitation state after suctioning the armature and generates the below effects.

• Reduced power consumption (by approx. one-fourth)

• Decreased generation of heat (by approx. one-fourth) by the stator (electromagnetic coil)

• Slimmer and more compact

[Wiring methods and Timing Charts]

Primary Control

Secondary Control